China Garments Sewing Machine Suppliers

Choosing the right sewing machine for a garment factory is essential for improving productivity, efficiency, and the overall quality of the garments produced. There are various factors to consider when selecting a sewing machine for garment factory:

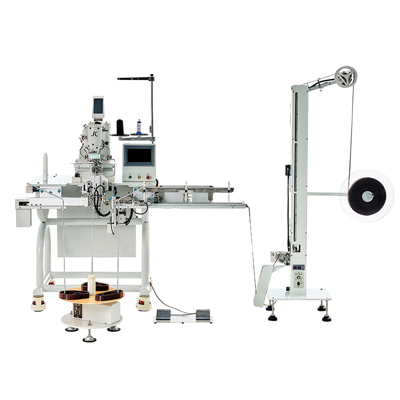

Machine Type: Industrial sewing machines are designed for heavy-duty use and can handle high-volume production. Look for machines suitable for the specific types of garments your factory produces, such as straight stitch machines, overlock machines, coverstitch machines, or specialized machines for intricate embroidery work.

Speed and Production Capacity: Consider the stitching speed of the machine, as faster machines can increase productivity. However, it\\\\\\\\\\\\\\\'s crucial to strike a balance between speed and stitch quality to ensure the garments meet quality standards.

Stitching Functions: Different garments require various stitching functions. Ensure that the sewing machine you choose can perform the necessary stitches, such as straight stitching, zigzag stitching, and other decorative stitches as required.

Durability and Reliability: Industrial sewing machines should be robust and able to handle continuous operation for extended periods. Look for reputable brands known for their durability and reliability.

Automation and Technology: Some modern sewing machines come with advanced features, such as computerized controls, automatic thread trimming, and programmable stitching patterns. These can improve efficiency and reduce human error.

Service and Support: Choose a sewing machine brand that provides good customer support, maintenance services, and readily available spare parts.

Ergonomics and Operator Comfort: Operator comfort is essential for long working hours in a garment factory. Select machines with user-friendly interfaces, adjustable sewing tables, and ergonomic features.

Budget: Determine your budget and try to strike a balance between quality and cost-effectiveness. While cheaper machines may seem attractive, investing in quality machines can lead to long-term savings through reduced downtime and maintenance costs.

What is the best sewing machine for a garment factory?

Choosing the right sewing machine for a garment factory is crucial for enhancing productivity and maintaining product quality. The best sewing machine will depend on the specific needs of the factory, such as the type of garments produced, the volume of production, and the desired features. Industrial sewing machines are commonly preferred in garment factories due to their high-speed capabilities, durability, and versatility in handling various fabrics. Brands like Juki, Brother, and Singer are well-regarded in the industry for their reliable performance. However, it is essential to consult with experienced professionals and conduct thorough research to select the ideal sewing machine that aligns with the factory\\\'s production requirements and budget constraints.

How to choose the right sewing machine for garment production?

Selecting the appropriate sewing machine for garment production involves a systematic evaluation of several factors. Firstly, assess the type of garments the factory specializes in and consider the required stitching techniques. Next, determine the expected production volume and speed requirements. Industrial sewing machines with features like automatic thread trimming and programmable stitch patterns can significantly boost efficiency. Additionally, examine the machine\\\'s durability and ease of maintenance, as these aspects are crucial for sustaining long production hours. Finally, don\\\'t forget to consider the after-sales service and support provided by the manufacturer, ensuring that any technical issues can be promptly addressed. By carefully analyzing these factors, garment factory owners can make informed decisions and invest in sewing machines that optimize their production processes effectively.

What are the benefits of using industrial sewing machines in garment factories?

Industrial sewing machines offer a myriad of advantages that make them indispensable in garment factories. Firstly, their high-speed stitching capabilities significantly increase production output, enabling faster completion of orders. The robust construction of these machines allows them to handle heavy and continuous use, ensuring extended durability. Many industrial models are equipped with advanced features like computerized controls, automatic thread cutters, and programmable stitch patterns, enhancing precision and efficiency in garment production. Furthermore, these machines can handle a wide range of fabrics, from delicate silks to heavy denim, catering to diverse garment styles. Overall, the incorporation of industrial sewing machines in garment factories not only streamlines production processes but also contributes to the consistent delivery of high-quality garments to meet market demands.

Are there any specialized sewing machines for specific garment types?

Indeed, various specialized sewing machines cater to specific garment types, allowing factories to achieve impeccable results. For instance, overlock machines are ideal for finishing the edges of knitwear to prevent fraying and create a professional look. Coverstitch machines are perfect for creating hems and topstitching, commonly used in activewear and sportswear production. Blind stitch machines are useful for inconspicuously sewing hems, making them suitable for dressmaking and formalwear. Additionally, factories producing intricate embroidery designs can benefit from embroidery machines that can stitch complex patterns on garments. By incorporating these specialized sewing machines into their production lines, garment factories can enhance the quality and craftsmanship of their products, giving them a competitive edge in the market.

How to maintain sewing machines in a garment factory?

Proper maintenance is essential to ensure the longevity and optimal performance of sewing machines in a garment factory. Regular cleaning and lubrication of the machine\\\'s moving parts help prevent dust and debris buildup, reducing the risk of malfunctions. Operators should be trained to recognize signs of wear and tear and report any issues promptly for timely repairs. Additionally, it is crucial to follow the manufacturer\\\'s guidelines for servicing and replacing parts to avoid unexpected breakdowns. Implementing a preventive maintenance schedule can significantly reduce downtime and production delays, maximizing the factory\\\'s overall efficiency. By investing time and effort into the care of sewing machines, garment factory owners can maintain a smooth and uninterrupted workflow, ultimately leading to improved productivity and profitability.