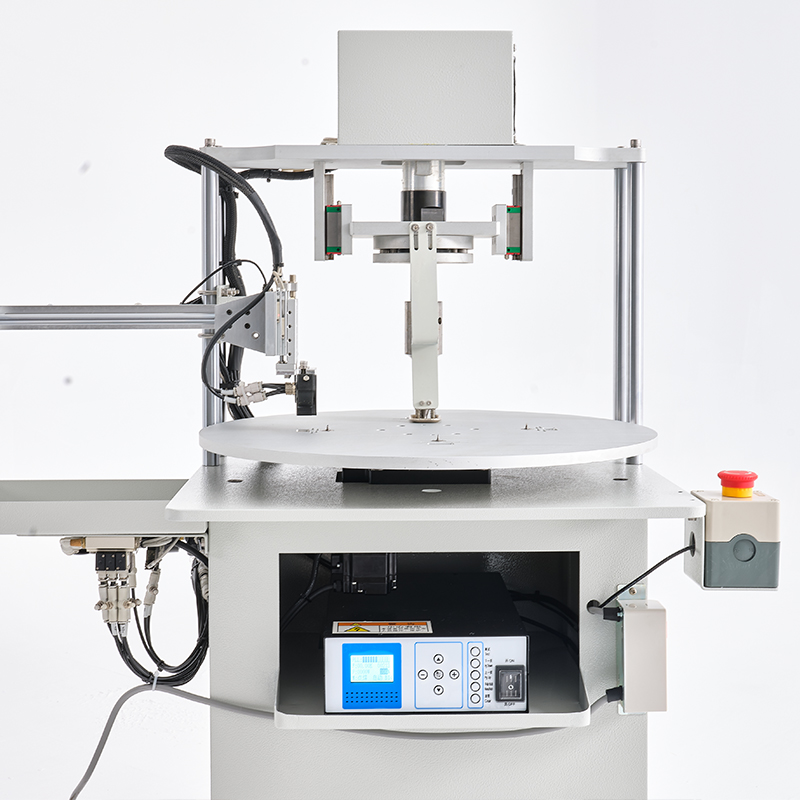

The Automatic Ultrasonic Holes Punching Machine (Model No. JYL-CC-01) is a high-performance, intelligent ultrasonic punching solution designed to meet the demands of modern textile processing, particularly in the cap and hat manufacturing industry. Powered by the latest smart circuit technology, this machine ensures stable, powerful ultrasonic performance while delivering precise and clean hole punching results.

With its modular mold design, flexible control system, and user-friendly operation, this Ultrasonic Punching Machine is ideal for industrial applications that require high-efficiency, customized perforation on materials like nonwovens, fabric, and synthetic textiles.

Core Product Features

Advanced Ultrasonic Technology

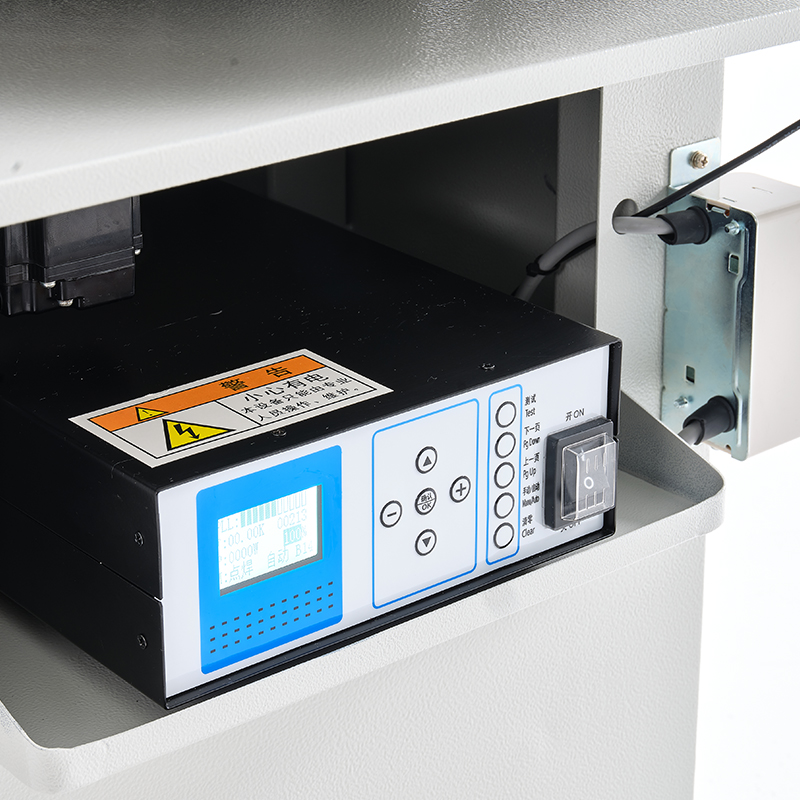

Utilizes a 20KHz 2000W ultrasonic system that delivers powerful and stable energy to punch clean holes without fraying, burning, or damaging the material.

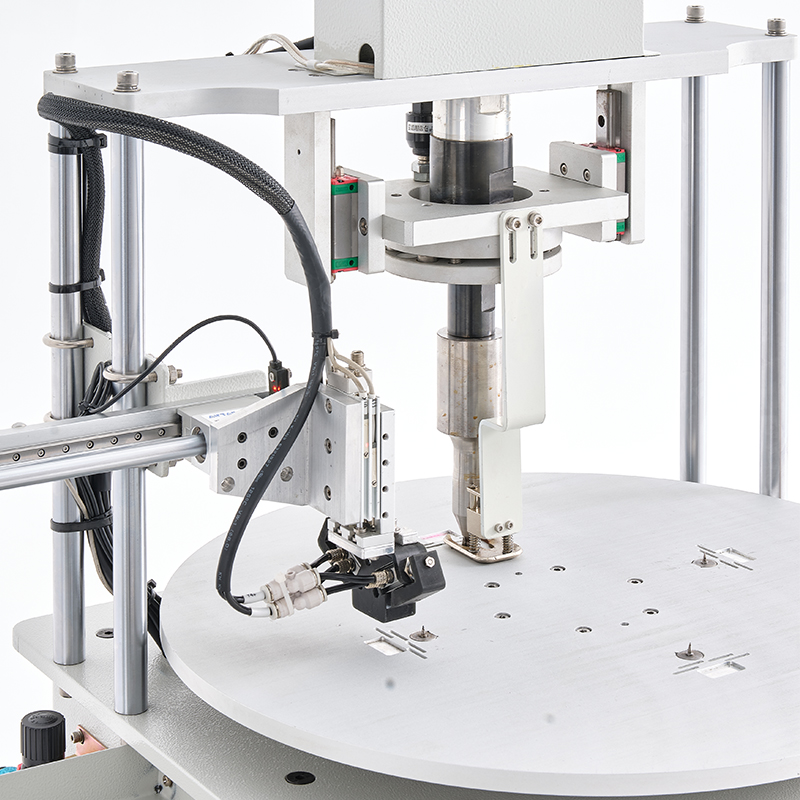

Flexible Mold Replacement System

The machine supports quick-change molds that allow users to easily switch between different punch shapes such as small animals, anagrams, heart shapes, and more. Multiple molds can be installed and operated within the same system.

Automatic Operation

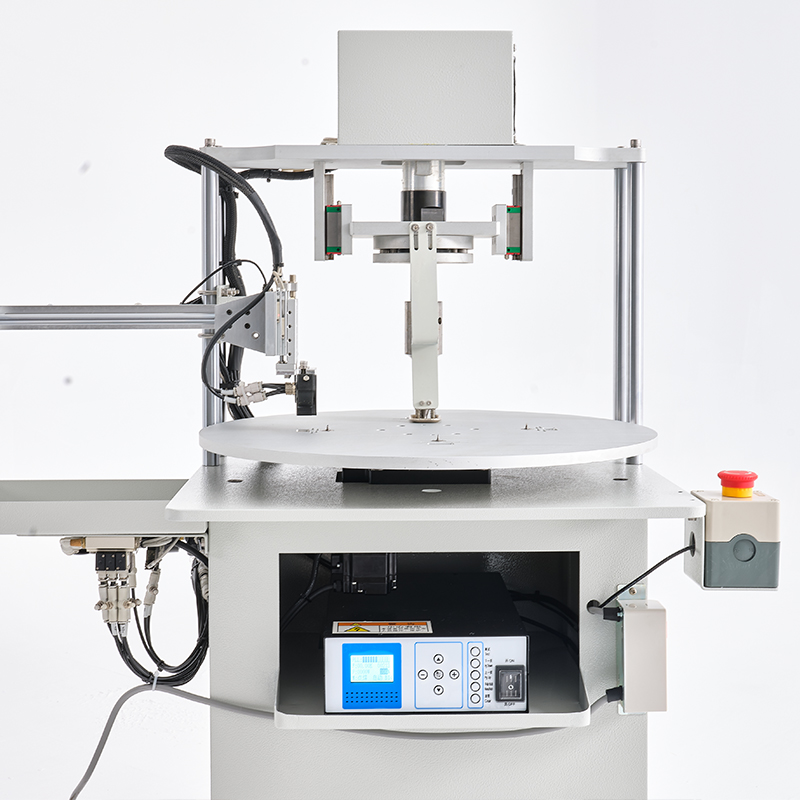

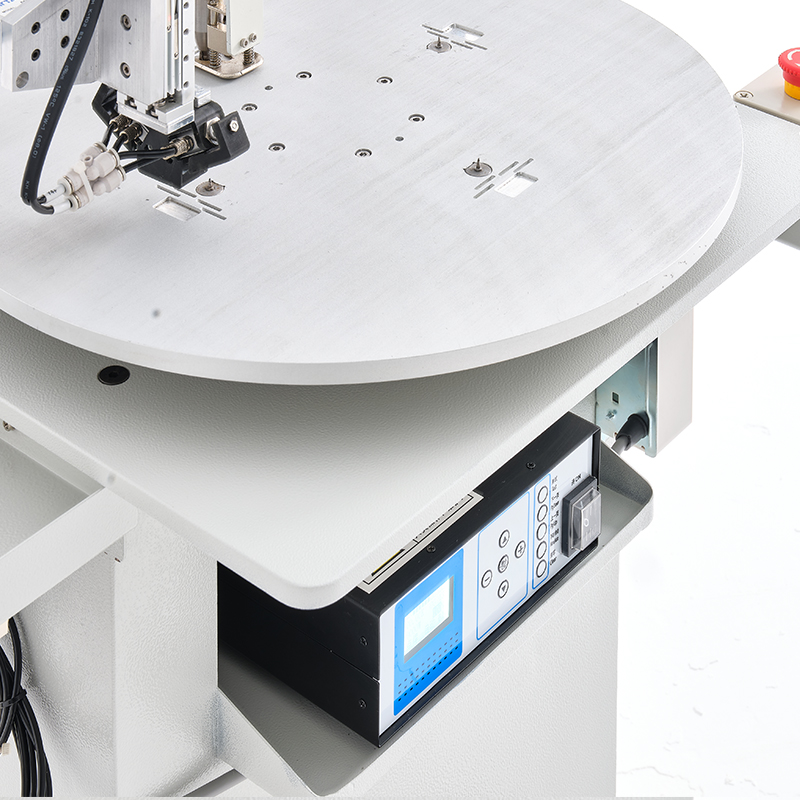

Equipped with PLC touch panel control and stepping motor rotation, the machine performs automatic rotary punching and material collection, greatly improving productivity and consistency.

Multi-layer Capability

Supports punching through multiple layers of fabric, making it suitable for various textile and layered synthetic applications.

Compact and Lightweight Design

With a machine size of 500 × 500 × 1250mm and a net weight of only 80KG, it’s easy to integrate into existing production lines or operate as a stand-alone workstation.

Product Specification

| Item No. | JYL-CC-01 |

| Motor | Stepping Motor |

| Controlling Way | PCL |

| Air pressure | 0.6Mpa 1.8L/min |

| Supersion | 20K 2000W |

| Operation Type | PLC Touch Panel |

| Supply voltage | 220V 50Hz |

| Total power | 2500W |

| Size | 500× 500 ×1250W |

| Net Weight | 80KG

|

Applications

This Industrial Ultrasonic Punching Machine is widely used in:

Cap and Hat Manufacturing – Precise punching on the panel of baseball caps, hat crowns, and other headwear.

Textile & Nonwoven Fabric Processing – Creating ventilation holes, decorative holes, and functional openings in multilayer fabrics.

Filter and Mask Material Perforation – Ideal for punching clean, uniform holes in synthetic and thermoplastic filter layers.

Customized Fashion & Accessories – Offers creative punching patterns for garment labels, patches, or decorative trims.

Smart control with user-friendly PLC touchscreen

Precise and burr-free ultrasonic punching performance

Supports complex shapes and customized molds

Fast mold changes and minimal maintenance

Compact design ideal for workshop or factory use

Efficient material handling and rotary automation