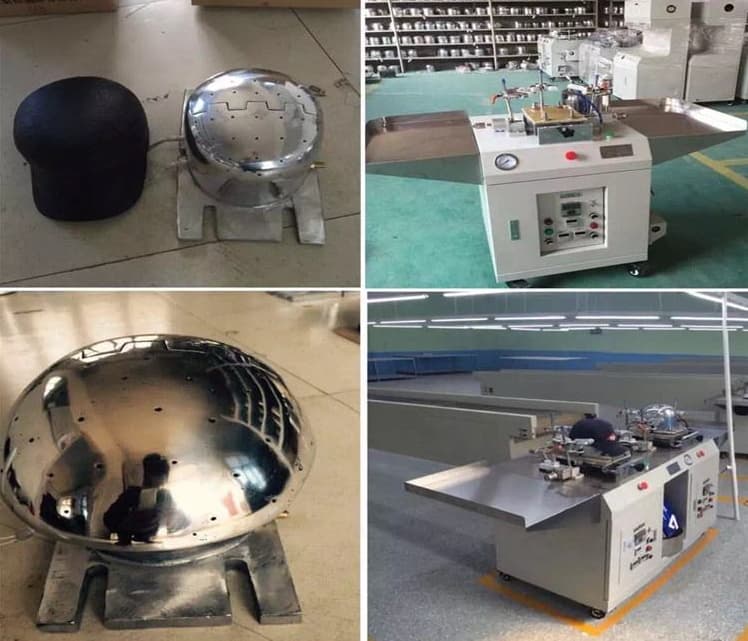

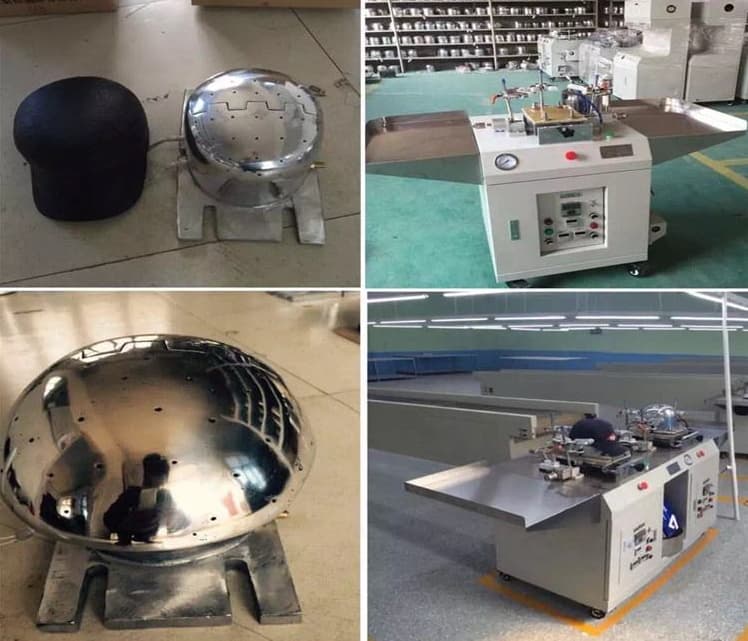

The Snapback Hat Blocking Machine is an advanced industrial solution designed for reshaping, blocking, and ironing snapback hats, baseball caps, and bucket hats with precision and efficiency. By combining water steam heating, stainless steel molds, and automated mechanical handling, this machine delivers consistent cap shaping results suitable for mass production environments.

As a professional Hat Blocking Machine Manufacturer, we provide reliable and intelligent cap shaping equipment widely used in modern hat factories and automated production lines.

Product Description & Value

This Cap Blocking Machine works by placing the cap upper onto a stainless steel mold, then applying controlled water steam through dual steamer heads. Steam penetrates both the inside and outside of the cap, softening the fabric and allowing it to be reshaped accurately. Once cooled, the cap maintains its intended form with excellent stability.

Equipped with an internal steam generator and optional cooling device, this Snapback Cap Blocking Machine significantly reduces labor costs while improving shaping consistency, making it ideal for high-volume production.

Key Features of the Hat Blocking Machine

Two-Head Steam System

Dual steamer heads increase productivity and support continuous operation.

Integrated Steam Generator

Automatic water filling ensures uninterrupted production, perfect for mass manufacturing.

Programmable Control System

Water volume, steam time, ironing time, and drying time are fully adjustable.

Stainless Steel Cap Molds

Durable, hygienic, and easy to install or replace to meet different cap styles.

Automatic Mechanical Hands

Hats are held and positioned automatically, minimizing manual handling.

Cooling Device Compatibility

Rear-mounted cooling system stabilizes caps quickly after reshaping.

This machine functions as a Hat Shaping Machine, Cap Shaping Machine, Hat Pressing Machine, and Hat Heat Press Machine all in one.

How Does a Hat Blocking Machine Work?

How does a hat blocking machine work?

Place the snapback hat or bucket hat upper onto the stainless mold

Lower the tool cover

Steam penetrates the fabric evenly

Cap becomes soft and moldable

Shape is fixed during cooling

Finished cap is released automatically

This process ensures uniform results and reduces deformation or fabric damage.

What Is a Snapback Hat Blocking Machine?

What is a snapback hat blocking machine?

It is a specialized Hat Molding Machine used to reshape, form, and iron snapback caps using steam, heat, and pressure. It is an essential piece of cap manufacturing equipment for factories producing structured caps and flat-brim hats.

Technical Specifications

| Item | Specification |

|---|

| Model | JYL-IC002 Automatic Heat Press Hat Machine |

| Power Supply | 220V |

| Power Consumption | 7KW |

| Dimensions | 1400 × 700 × 1300 mm |

| Weight | 260 KG |

| Air Pressure | 4–6 kg/cm² |

| Packing | Plywood case with steel pallet |

Applications

This Snapback Hat Forming Machine is widely used in factories seeking consistent quality and high output.

Supplier & Manufacturer Advantages

As a trusted Hat Blocking Machine Supplier and Hat Blocking Machine Manufacturer, we offer:

Industrial-grade machine design

Stable steam and heat shaping performance

Custom mold options for different hat styles

Optional PLC control systems

Reliable after-sales technical support

We support OEM / ODM requirements and bulk orders for global markets.

FAQ

Q1: Can this machine be used for bucket hats?

Yes, with suitable molds, it works as a Cap Molding Machine for bucket hats and snapback caps.

Q2: Is the machine fully automatic?

It is semi-automatic to fully automatic depending on configuration, including optional PLC systems.

Q3: Does it support mass production?

Absolutely. The built-in generator and automatic handling make it ideal for continuous factory use.

Q4: Can cooling devices be added?

Yes, a rear cooling system can be matched for faster shape fixing.