Fully Automatic Webbing Cutting and Joining Machine

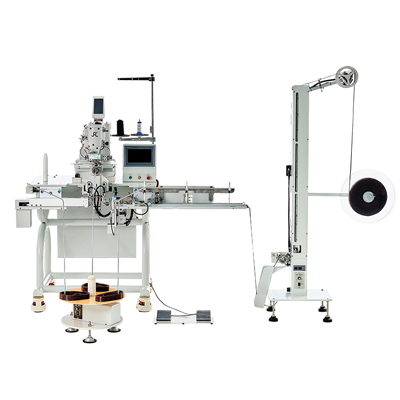

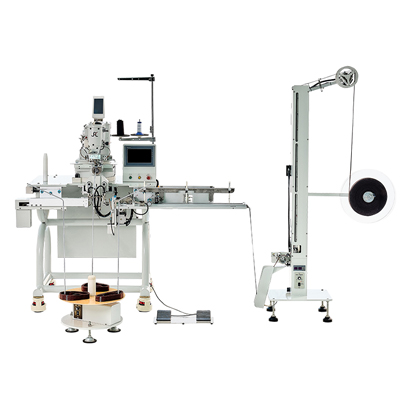

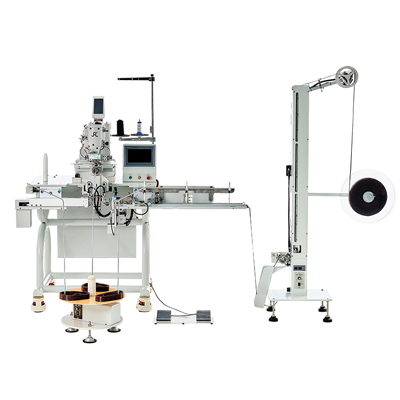

Looking for a high-performance Automatic Strap Sewing Machine that delivers precision, speed, and automation? Our model JYL-B6050D-XJ offers a fully automated solution for strap processing, from feeding, cutting, to sewing, making it ideal for manufacturers of caps, backpacks, garments, shoes, safety gear, and more.

Whether you are upgrading from a manual process or searching for an advanced strap joining machine, we provide scalable solutions to meet your production needs. This machine integrates smoothly into automated production lines and is perfect for large-scale Automatic Strap Sewing Machine Sales and OEM or ODM requirements.

Product Specification

Product Specification

| Machine No. | JYL-B6050D-XJ |

| Working Area | L: 80-200mm/ W:160-220mm |

| Maximum Sewing Speed | 2700r.p.m |

| Stitch | 0.05-12mm |

| Maximum No.of Stitches | 20000stitches /pattern |

| Work holder method | Penumatic |

| Medium Presser Height | 15mm |

| Motor | 750w Direct-drive Servo Motor |

| Applicable Needle | DPx17 DPx5 |

| Air pressure | 0.5Mpa 1.8L/min |

| Stored programs | 1-999 patterns |

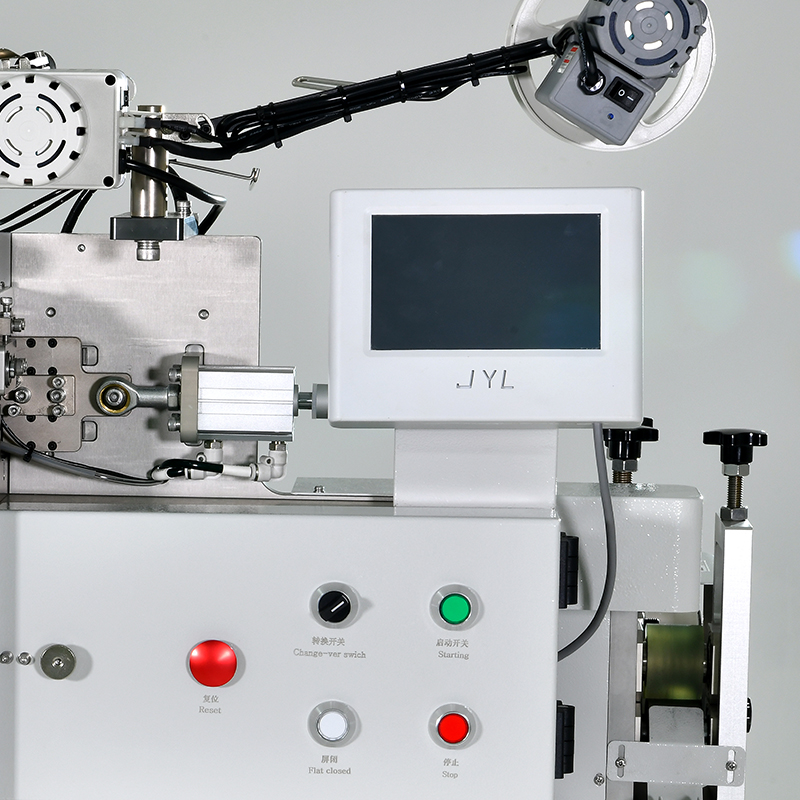

| Operation Type | 7.5’ Lcd Touch Panel |

| Supply voltage | AC 220v single phase |

| Size | 1080x1200x1550MM |

| Weight | 400KG |

Main Features

Automatic detection joint,automatic counting.

Automatic feeding and cutting ,automatic cut-off for material breakage.

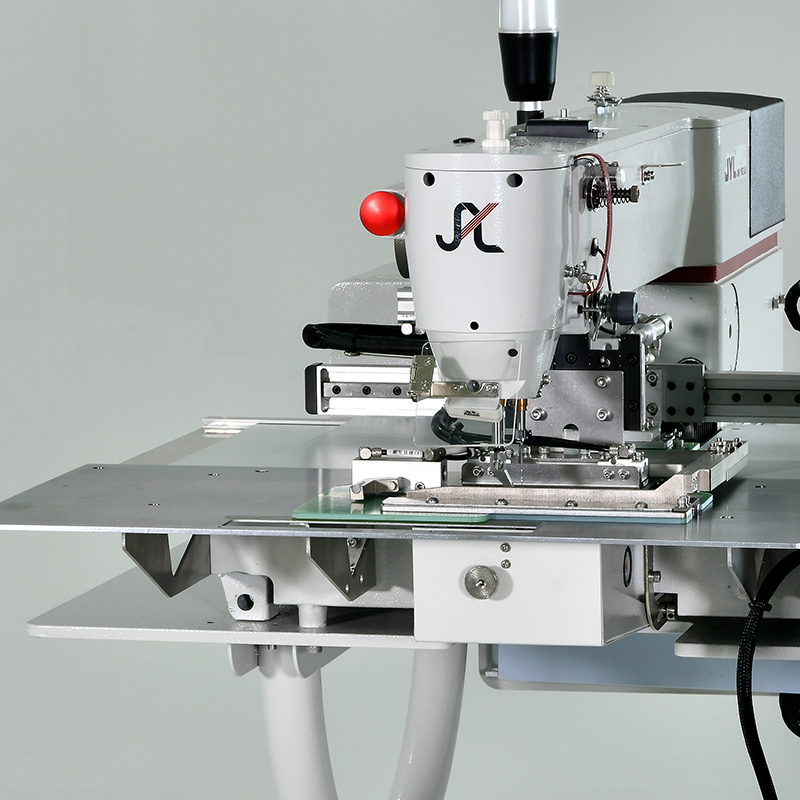

Measure the length of the ribbon,cut it off,fold and sew it.

Product Description

|  |  |  |

Winding threads in precise quantity by using electronic winding function. | Air pressure alarm (Alarm function activate when air pressure lower than 0.4 pa) | Automatic stripdrawing and ironing function | Warning alarmfunctions, machine canshutdown automatically when lack of bottom thread,thread breakage,needle breakage |

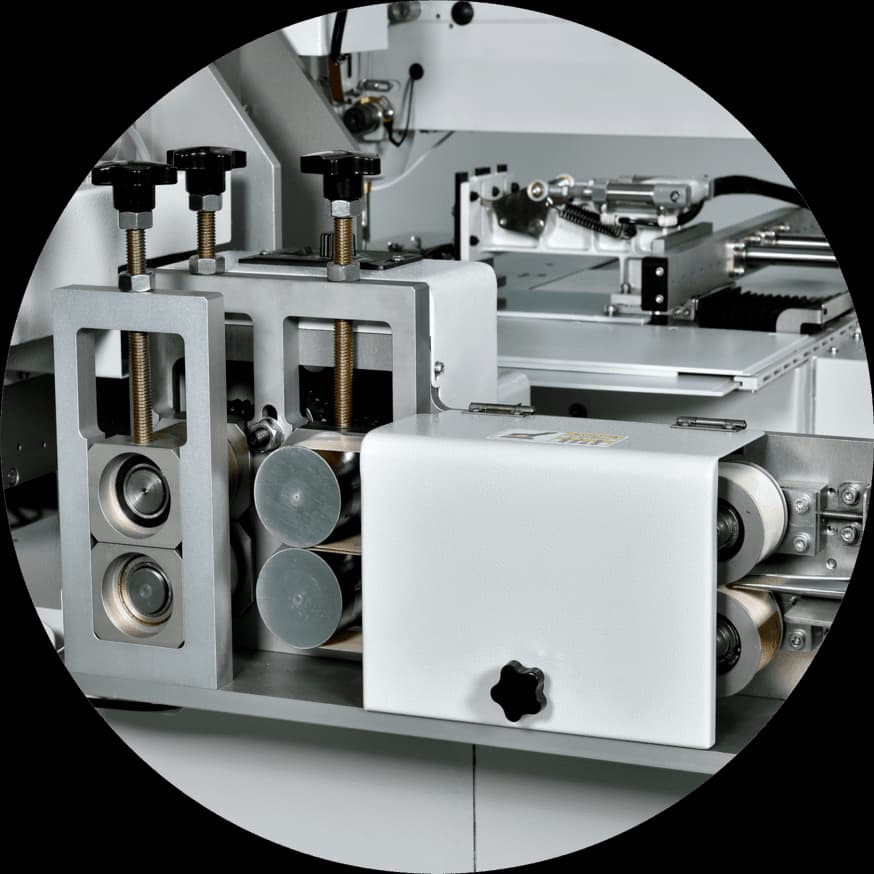

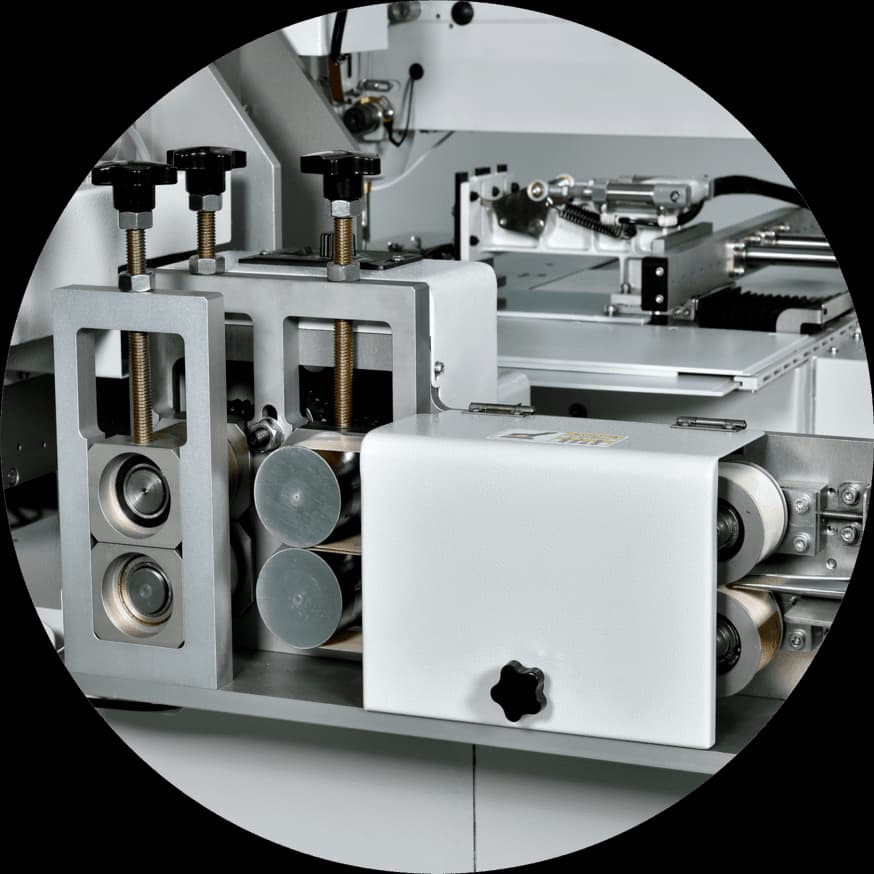

Advanced Features of Our Automatic Webbing Sewing Machine

This programmable strap sewing machine is equipped with intelligent control systems and high-speed stitching, making it suitable for both industrial and mid-scale production. As a CNC Strap Sewing Machine, it combines software flexibility with hardware precision.

Automatic measurement, feeding, and cutting of webbing lengths via the LCD touch screen.

Integrated strap joining machine function detects strap joints and accurately folds and stitches them.

Programmable memory supports up to 999 patterns and 20,000 stitches per pattern.

Industrial performance with sewing speed up to 2700 rpm and stitch length adjustable from 0.05 to 12mm.

Built-in safety system includes thread winding detection, air pressure alarms, and automatic stop on thread or needle breakage.

Suitable for Backpack and Apparel Manufacturers

For backpack production, this Automatic Strap Sewing Machine for Backpack is an ideal choice. The machine’s working area of 80 to 200mm in length and 160 to 220mm in width supports various types and sizes of webbing, including nylon, polyester, and cotton. It also performs well in garment, footwear, and tactical gear production.

As an Automatic Webbing Sewing Machine, it is capable of replacing multiple manual processes, significantly improving productivity and reducing labor costs.

Applications of Strap Sewing Machines

This industrial strap sewing machine is widely used in:

Backpack and bag strap sewing

Cap and headwear webbing loops

Footwear heel and tongue loops

Garment labels and decorative webbing

Tactical and military gear production

Sports equipment and safety harness sewing

The programmable and CNC functions allow for repeatable, accurate sewing patterns in both short runs and mass production.

Why Choose Us as Your Custom Strap Sewing Machine Manufacturer

We are a reliable custom flexible sewing machine manufacturer offering full automation and customization. Our CNC strap sewing machine solutions are proven in various industries with ongoing technical support and fast delivery.

Customization available for sewing area and programming

Intelligent alarm systems and real-time monitoring

High stability for continuous industrial use

Global delivery and remote installation support

Flexible models for various webbing and straps

We provide complete solutions for businesses seeking an efficient strap joining machine or a fully integrated automatic webbing sewing machine. Whether you manufacture backpacks, sports gear, or industrial safety equipment, our sewing machine improves output and maintains consistent sewing quality.

Contact us today for:

Product Specification

Product Specification