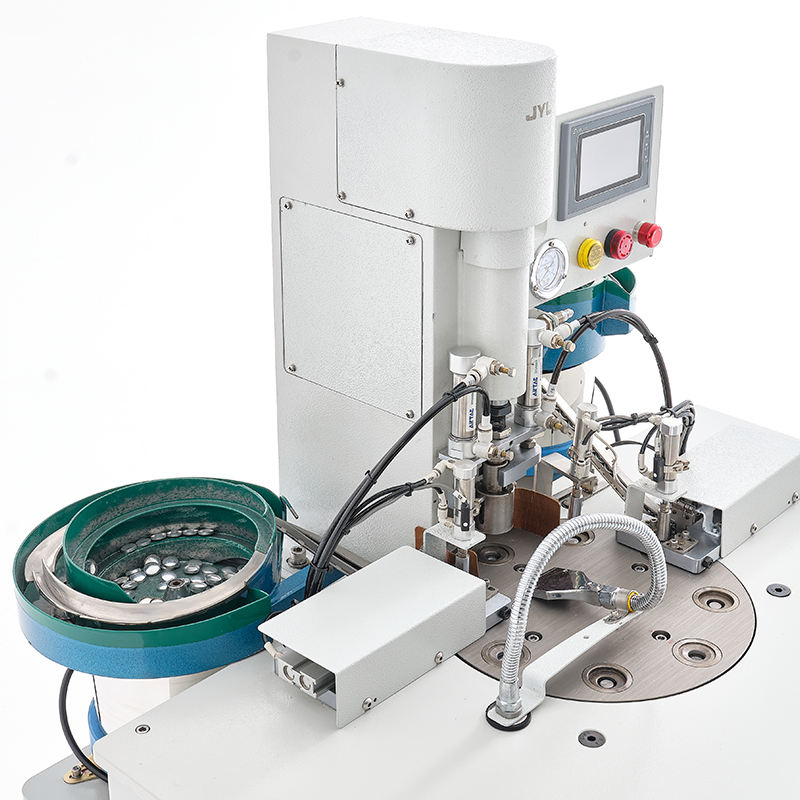

Fully Automatic Fabric Covered Button Pressing Machine

The Button Fabric Covering Machine is a fully automatic solution designed to revolutionize the process of producing fabric-covered buttons. Ideal for garment factories and clothing accessories manufacturers, this advanced Fabric Covered Button Making Machine combines automation, safety, and productivity into a single user-friendly system.

Product Overview

The Button Covering Machine model JYL-G6-01 enables users to achieve high-speed, uniform button covering with minimal labor. With the ability to produce up to 1500 buttons per hour and a daily output of 20,000–30,000 pieces, it significantly enhances operational efficiency. Its automated design includes fabric feeding, button placement, fastening, and removal of defective or upside-down parts—all performed without manual intervention.

This machine is compatible with a wide variety of button types including two-hole, four-hole, and shank buttons, making it a versatile tool for shirts, coats, uniforms, and more.

Key Features

Fully Automatic Operation: Simply place the fabric into the feed system and press the switch. The machine performs the entire process automatically—from feeding to fastening and discharge.

Efficient Button Production: With a processing speed of 30–40 pieces per minute, this Fabric Covered Button Making Machine offers rapid and consistent output.

Uniform Button Quality: Every wrapped button comes out with identical shape and precision, ensuring professional-level consistency.

Automatic Button Feed System: The upper buttons are automatically supplied by the system, eliminating the need for manual loading.

Upside-Down Rejection System: Misoriented buttons are automatically detected and discharged, minimizing defective output.

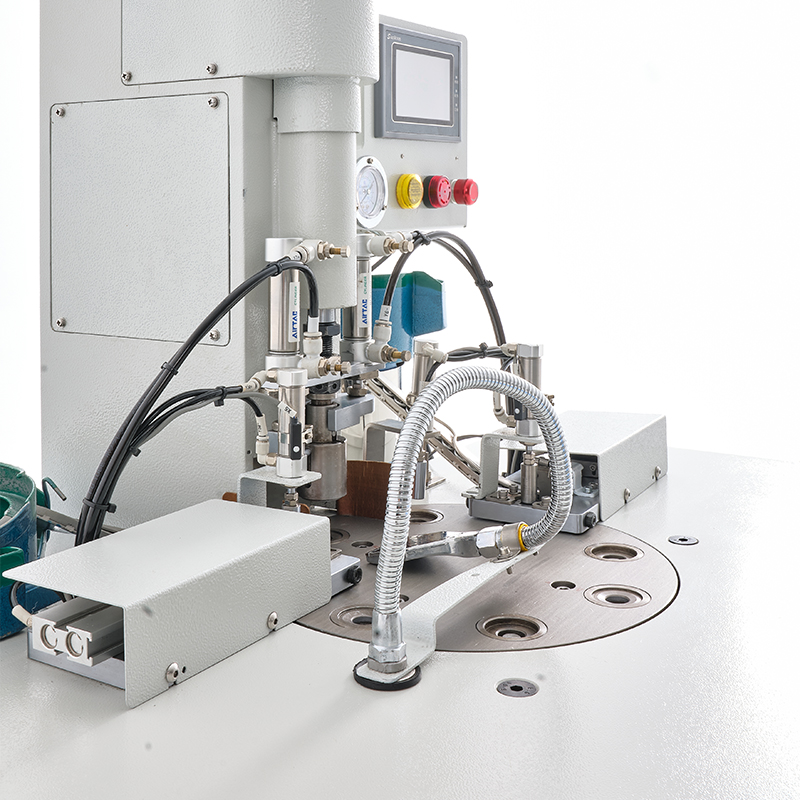

Pressure Monitoring System: Air pressure alarms activate when levels drop below 0.4Mpa, protecting both product quality and operator safety.

Product Description

1. Just put the fabric in, press the switch, the device automatically completes the buckle.

2. Calculated according to 8 hours per day, the production volume is 20000-30000.

3. Wrapped buttons, the shape is exactly the same.

4. The upper button is automatically supplied by the device supplier.

5. Air pressure alarm (Alarm function activate when air pressure lower than 0.4 pa).

Product Specification

| Item No. | JYL-G6-01 |

| Motor | Stepping Motor |

| Controlling mode | PLC |

| Air pressure | 0.6Mpa 1.8L/min |

| Operation Type | PLC Touch Panel |

| Supply voltage | 220V 50Hz |

| Total power | 3000W |

| Capacity | 30-40piece/min |

| Size | 800×750×1200mm |

| Net Weight | 140KG |

Application Scope

This Button Fabric Covering Machine is suitable for fabricating a range of covered buttons used in:

Its precision and flexibility make it an indispensable piece of equipment for textile and garment production lines.

Why Choose This Fabric Covered Button Making Machine?

Whether you're producing small-batch fashion pieces or mass-manufactured uniforms, the Button Covering Machine delivers high productivity with minimum supervision. It reduces labor costs, improves product consistency, and enhances workplace safety—making it a smart investment for modern clothing manufacturers.

FAQ - Button Fabric Covering Machine / Fabric Covered Button Making Machine

Q1: What is a Button Fabric Covering Machine?

A: A Button Fabric Covering Machine, also known as a Fabric Covered Button Making Machine, is an automatic device designed to wrap fabric over button molds and press them into finished fabric-covered buttons. It significantly boosts productivity and ensures uniformity in button appearance.

Q2: What types of buttons can this machine produce?

A: This machine is suitable for producing two-hole, four-hole, and shank fabric-covered buttons, making it ideal for shirts, jackets, coats, workwear, and more.

Q3: How many buttons can it produce per hour?

A: The Fully Automatic Fabric Covered Button Pressing Machine can produce up to 1500 buttons per hour, depending on fabric type and operator coordination.

Q4: Does it require multiple operators to function?

A: No, the machine is designed for single-person operation. One person can control both the fabric covering and button securing functions simultaneously.

Q5: Is the feeding and discharging process manual?

A: No, the Button Covering Machine features automatic feeding of the upper button, automatic correction of offset bottom buttons, and automatic discharge of upside-down pieces.

Q6: What power source and air pressure are required?

A: The machine operates on a 220V, 50Hz power supply and requires an air pressure of 0.6Mpa with a minimum air flow of 1.8L/min. An air pressure alarm alerts the user if the pressure drops below 0.4Mpa.